|

| October 02, 2018 | Volume 14 Issue 37 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Pistons made of sapphire? Mid Michigan Research selects Insaco for critical part fabrication

Dr. Harold Schock is a Professor of Mechanical Engineering at Michigan State University and founder of a research firm called Mid Michigan Research LLC, which is focused on improving the efficiency of internal combustion (IC) engines.

Dr. Schock's firm had been engaged over the years to analyze information obtained by visualizing combustion in situ, that is, within an actual pressurized cylinder with spark ignition. Their research indicated that greater vision and research flexibility will be created by using a fabricated cylinder matching the engine geometries under study.

Combustion contained within a cylinder creates extreme conditions of heat, pressure, and possibly abrasion. Although glass might be considered as a first choice for an optically accessible cylinder, it was quickly determined that ordinary glass would not survive. Fused quartz is stronger than glass blends but is difficult to fabricate in engine-cylinder sizes and has limited transmission of infrared rays at higher temperatures.

Dr. Schock's team understood that sapphire is the second-hardest natural material, surpassed only by diamond. This single-crystal form of Al2O3 or aluminum oxide, would therefore be a superior choice due to extreme resistance to abrasion, very high working temperature (1,950 C), and full-spectrum transmission even at high temperatures. Industrial sapphire, however, is commercially grown as a very pure crystal, but the result is one solid piece. This large crystal must then be machined to the desired size and form. This requires diamond grinding technology and special techniques for handling forms without damage. Insaco Inc., because of its superior machining capabilities and knowledge of machining sapphire, was the logical choice.

Founded in 1947 to fabricate parts from sapphire, Insaco -- the name is a contraction of INdustrial SApphire COmpany -- began by machining phonograph needles made from sapphire. Insaco pioneered many techniques for custom fabrication of precision parts from sapphire and has always supported customers in need of extreme precision -- and often unusual forms. Scott Mittl, sales engineer with Insaco for over 25 years, says, "One of Insaco's main specialties has been the development of techniques used for precision fabrication and polishing to optical standards of parts with IDs and ODs."

Since the 1980s and 1990s, these special techniques were useful in fabrication and polishing of several designs of large sapphire cylinders for various OEMs on three continents that were conducting IC engine research. These cylinders, with sizes up to 6 in. length and 3 to 4 in. diameter, were fabricated to specifications requiring diameter tolerances and cylindricity to .0008 in. Considering that a human hair is about .003 in. diameter, achieving these tolerances in this difficult material is remarkable.

VIDEO: Profile of Insaco by Design2PartTradeShow.

Professor Schock and his team have been performing in-situ laser observations of fuel-air mixing and flame front propagation in such cylinders for over three decades. Results have shown the importance of having combustion chamber geometrical configurations that are exact duplicates of the metal configuration of interest. What evolved was a design goal to fabricate a piston from sapphire to achieve more precise measurement of the physical processes that govern the performance of a given engine.

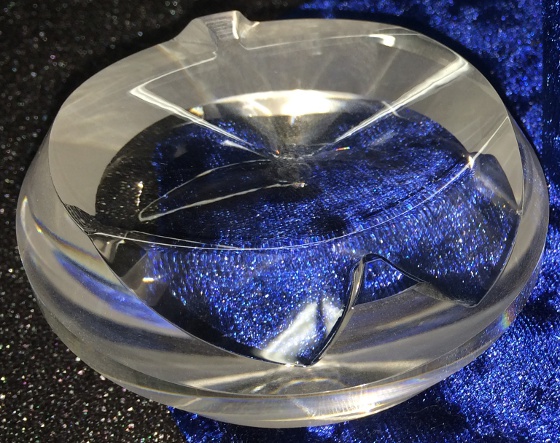

Fabrication of a simple polished sapphire puck, representing a flat piston top, was easy to do. But what the researchers really wanted was a piston head with unique contours to test their theories on how piston head form could control -- and thus optimize -- combustion in a real environment.

Insaco again was able to pioneer new techniques, for both fabrication and polishing of these asymmetric forms in sapphire, to tolerance levels that exceeded the Mid Michigan Research parameters. The photos (below) provide a glimpse of one such design that continues to undergo contract testing for careful analysis of form versus combustion pattern under varying conditions.

According to Professor Schock, "Insaco has been a reliable partner over many years. These are complicated parts, and understandably expensive to fabricate from sapphire, but critical to the success of our research programs."

About Mid Michigan Research, LLC

Mid Michigan Research provides comprehensive solutions for in-cylinder research and analysis of internal combustion engines (gasoline and diesel). Their products include: CASE (a ring-pack and piston dynamics software simulation tool), optically accessible engines for research and imaging, and research services for in-cylinder imaging and engine studies. To learn more about Mid Michigan Research, call 313-506-8049 or visit their website www.mmrllc.com or email harold.schock@mmrllc.com.

About Insaco

Insaco, Inc. provides precision machining in ceramics, sapphire, quartz, and other hardened glass or crystalline materials for an array of industries including aerospace, defense, semiconductor, instrumentation, and research. For over 70 years, Insaco has been a leader in high-precision fabrication where close tolerances and geometries are critical. Insaco's ability to exceed customer requirements, coupled with unusually stringent inspection practices, has been the hallmark of the company's success. To learn more about Insaco, visit the company's Facebook page, website at www.insaco.com, call 215-536-3500, or email sales@insaco.com.

Published October 2018

Rate this article

View our terms of use and privacy policy